The F900 is the Most Capable System on the Market for Companies Who Need Large, 3D-Printed Production Parts in Small or Large Volume.

The F900 is specifically built for manufacturing and aerospace. (Photo courtesy of PADT)

PADT unloads the HUGE F900 at its Tempe headquarters. (Photo courtesy of PADT)

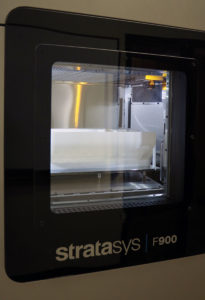

TEMPE, Ariz., August 29, 2019 ─ In an exciting development that enhances its additive manufacturing services and capabilities, PADT, a globally recognized provider of numerical simulation, product development, and 3D printing products and services, added a Stratasys F900 Fused Deposition Modeling (FDM) Additive Manufacturing System at its headquarters in Tempe, Arizona. With fast build speed and large build volume, the F900 significantly increased PADT’s 3D Printing capability and capacity.

“The addition of the F900 flagship FDM printer to our growing lineup of additive manufacturing systems is a major milestone in our long-term partnership with Stratasys,” said Ward Rand, co-founder and principal, PADT. “This move greatly enhances the capabilities we provide our customers based on Stratasys’ leading-edge equipment.”

With fast build speed and large build volume, the F900 significantly increased PADT’s 3D printing capability and capacity. (Photo courtesy of PADT)

The Stratasys F900 is specifically built for manufacturing and aerospace. With the largest build size of any Stratasys FDM system, it’s designed to handle the most demanding manufacturing needs. The system uses a wide range of thermoplastics with advanced mechanical properties so parts can endure high heat, caustic chemicals, sterilization and high-impact applications.

FDM is the most common additive manufacturing process because of the technology’s ability to provide robust parts quickly at low-cost. PADT has developed expertise with the FDM printing process over the past 20 years. The Stratasys F900 is the pinnacle of FDM technology because it’s designed to meet the needs of the manufacturing industry’s shift from prototyping towards production parts. The addition of the F900 comes at a critical time for PADT due to the increased demand from its customers in industries such as aviation, space and defense, to create end-use components created under ISO9001/AS9100 standards.

The F900 has the largest build size of any Stratasys FDM system. (Photo courtesy of PADT)

“When we added a large stereolithography machine in 2018, we quickly learned how significant the demand is for more materials, larger parts, and faster turnaround,” said Rey Chu, co-founder and principal, PADT. “The Stratasys F900 fulfills all three of these same requirements for companies who need the outstanding performance of parts made with the FDM process. We look forward to partnering with our customers to make innovation work with this new capability.”

This new system will augment PADT’s existing fleet of four FDM systems from Stratasys. It will compliment Stereolithography, PolyJet, Selective Laser Sintering, and Digital Light Synthesis systems. This wide range of material and process choices is why hundreds of companies rely on PADT as their Additive Manufacturing services provider.

To learn more about PADT and its services, please visit www.padtinc.com.

About PADT

Phoenix Analysis and Design Technologies, Inc. (PADT) is an engineering product and services company that focuses on helping customers who develop physical products by providing Numerical Simulation, Product Development, and 3D Printing solutions. PADT’s worldwide reputation for technical excellence and experienced staff is based on its proven record of building long-term win-win partnerships with vendors and customers. Since its establishment in 1994, companies have relied on PADT because “We Make Innovation Work.” With over 80 employees, PADT services customers from its headquarters at the Arizona State University Research Park in Tempe, Arizona, and from offices in Torrance, California, Littleton, Colorado, Albuquerque, New Mexico, Austin, Texas, and Murray, Utah, as well as through staff members located around the country. More information on PADT can be found at www.padtinc.com.